Pinnacle Technologies offers a full line of Contact Wheels to suit all of your belt polishing needs.

Whether your process is robotic, automatic, or an off-hand application, we have the wheels that are right for the job. Our elastomer wheels offer high-quality technical performance, combining the maximum characteristics of resistance to loads and dynamic properties. The high resistance to deformation and continuous stresses makes it the ideal material for processing products with a strong design and critical applications.

Additional features that enhance the quality of this material are the high impact elasticity, good resistance to abrasion, mineral oils, fats, and aging. All our products made with Vulkollan® coatings have an excellent long-life span and maintain their value over time

SOLID COATING

Optimal result in finishing processes. Flexible abrasive belts, very fine grits.

GROOVED COATING

Different grooving patterns, (inclination degrees and Land:Groove ratio) increase/decrease the abrasive belt’s cutting action.

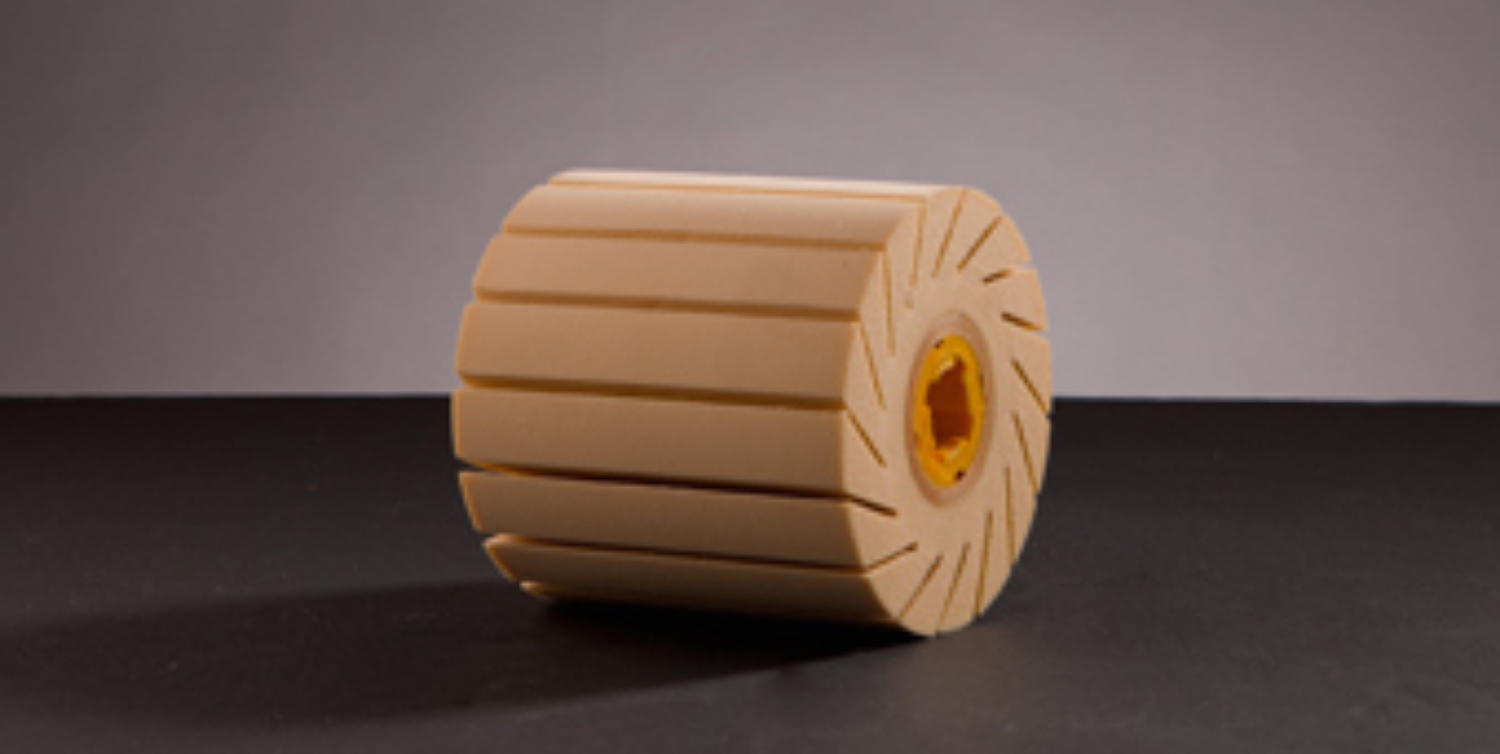

SEGMENTED COATING

10mm wide segments horizontally assembled, to ensure high performance and longer belt lasting. On-demand, segments inclination can be changed to enhance the finishing quality of the worked pieces.

Contact Wheel Overview

SEGMENTED COATING

10mm wide segments horizontally assembled, to ensure high performance and longer belt lasting. On-demand, segments inclination can be changed to enhance the finishing quality of the worked pieces.

SKINNY FLAPS COATING and VULKOLLAN® & SPONGE COATING

SKINNY FLAPS COATING - 5mm segments wide. Despite being very flexible, it ensures a strong wearing resistance and a notable belt performance.

VULKOLLAN® & SPONGE COATING - Remarkable cut flexibility and aggressiveness for a high belt performance. Due to the different densities of the two materials, their alternate sequence simulates the effect of a grooved coating but also exploiting the segmented version.

APPLICATION:

Excellent functionality in machining non-ferrous metals (brass, Aluminum, Zama, bronze). With regards to different types of wheels, the flexibility and cut aggressiveness may change, but still offering an optimal result in grinding and finishing processes of contoured and smooth pieces.

Standard coating thickness 20-25 mm; on-demand 45mm is also provided.

- Generally used with flexible abrasive belts:

Coarse grits => Hard coating 40/45 shore A.

Fine-Medium grits => Soft-medium coating 20/25-30/35 shore A.

Main areas of application:

Manufacture of fittings, handles, medical products, etc.

VENTILATED WHEEL

CHARACTERISTICS: High adaptability to profiled parts, good aggressiveness.

APPLICATION:

Deburring and finishing operations of contoured items. This product had been initially created in order to be adaptable to shapes of taps, then its application widened from car industry to steel chairs production, etc. The special crossing of the flaps produces an excellent belt cutting action, leaving less roughness on the workpiece than the grain of the belt used. It is not a coincidence that, when it is used with belts from coarse to fine grains, it grants excellent results both in grinding and finishing workings. By varying the working speed, the wheel may become perfectly adaptable to the different finishing targets.

Abrasive belts: flexible, from grits 60 to 320/380.

USE:

Manual, automatic machines, and robots (automatic belt tension recovery is necessary).

Do not exceed working speed indicated on the products.

NEOPRENE MOUSSE WHEEL

Coating: Neoprene foam, standard height 45mm.

CHARACTERISTICS: High flexibility and extreme softness.

APPLICATION: Finishing operations on shaped items (handles, taps).

Reduced working speed to exploit flexibility and softness.

USE: Manual, automatic machines, and robots.

COTTON-SPONGE WHEEL

Sponge segments wrapped into cotton layers.

Standard coating height 70mm.

CHARACTERISTICS:

Extreme flexibility, suitable for working on very profiled pieces.

SOFT COATING

- for finishing processes (2 cotton layers).

HARD COATING

- for grinding processes (4 cotton layers).

By adding neoprene flaps, belt cutting action will improve, obtaining a more aggressive wheel.

APPLICATION:

Working of non-ferrous metals such as brass and Aluminum; used on pieces with special design such as handles, office chairs basis, etc.

USE:

- Manual, automatic machines and robots.

LEATHER & SPONGE WHEEL

Leather and Sponge flaps. Standard height 50mm.

CHARACTERISTICS:

High resilience and adaptability of the coating; Indicated for the working of handles, taps, fittings in general and contoured parts. Low working speeds are recommended to exploit its softness and flexibility.

APPLICATION:

Dry working.

Grinding and finishing operations with J Flex belts.

USE:

- Manual, automatic machines, and robots.

PLASTICELL WHEEL

CHARACTERISTICS:

Wheel made by a light resin core with good mechanical performance. Resilient coating with remarkable resistance to heat and wearing. PLASTICELL wheel has been studied to satisfy the request of our customers in terms of economic issues still demanding a highly competitive product. It positively affects costs related to waste disposal (compared to metallic waste) and transport due to being very lightweight. The flexible cushion of PU foam, optimal elasticity, and competitive resistance to heat and abrasion.

APPLICATION:

Dry working of all metals such as brass, Aluminum, etc. (handles, taps).

USE:

- Manual, automatic machines, and robots.

Rubber

The chemical composition of our rubber ensures a high resistance to wearing as well as to hydrocarbons, chemical emulsions, and oils; it also offers excellent elasticity and mechanical performance.

COATING

The choice between a solid or grooved wheel depends upon the type of work.

For high stock removal, the ideal version is the grooved one where the correct inclination and ratio of the grooving pattern (Land:Groove), contributes to achieving the perfect performance. The smooth-coated wheel together with fine belts is suggested for finishing operations.

Standard rubber height 15/20mm.

SOLID RUBBER WHEEL

Ideal for metal finishing procedures with fine grain abrasive belts.

GROOVED RUBBER WHEEL

Used for all metal types, ideal for both fettling and finishing according to the hardness of the coating. The Land:Groove ratio improves the cutting action of the belt, avoiding its polishing and giving it a longer-lasting performance.

Abrasive belts:

- fine grains, low rubber hardness

- coarse grains, high rubber hardness.

METAL TUBES AND SHEETS

Rubber rollers produced with different characteristics which, depending on the working phases, are used in feeding systems, in grinding or finishing processes of steel and Aluminum pipes.

They can be mounted on both centerless systems for the grinding of round tubes and on machines for grinding of bars and square profiles, as well as on tube weld grinding units for removing the external weld bead on stainless steel pipes.

USE:

- Ideal for dry and wet production processes.

RUBBER WHEEL WITH CROSS GROOVED SLOTS

Considerable improvement of the belt performance in terms of cutting action and lasting thanks to the peculiar crosscut grooving set. Low rubber hardness to be used for profiled parts (Aluminum and iron radiators), higher rubber density for high stock removal.

USE:

- To be used with several grits.

EXPANDING RUBBER WHEELS

Self-Expanding rubber wheels with Aluminum cores are widely mounted on manual or automatic machines. Mainly found in the footwear industry, these wheels are mounted on Toupie or on multi-head machines for wooden parts.

They can also be used for fettling, smoothing of welding parts, glazing, etc.

SELF-EXPANDING RUBBER HOLDERS WITH SHANK

These items self-expand thanks to the centrifugal force keeping securely hold the abrasive sleeve. They find a large range of applications, from mold finishing to metal parts fettling, from beveling of sharp corners to the finishing of shaped parts, etc. They are principally assembled on portable machines and flexible shafts.

PNEUMATIC DRUMS

The pneumatic rubber wheel is made of an Aluminum hub and a rubber tire that can be inflated by adjusting the wheel’s air pressure, controlling the cutting action. They are mainly assembled on both portable and stationary machines. Thanks to its great elasticity and adaptability it is suitable for a wide range of applications such as work on stainless steel, Aluminum, carbon steel, plastics, wooden parts (back of chairs, sofa, edges of tables) glazing of various types of metals, footwear, glass, marble, etc. Used also for flat grinding, it remarks its excellent ability to conform to the contours of the workpiece.

Spare parts available:

- Steel shafts M14

- Rubber tires.

EXPANDING PU FOAM ROLLERS

PU foam centrifugal expanding rollers with 6mm double key-way suitable for grinding/finishing operations on portable machines and flexible shafts.

Silicone Rubbers

Silicone rubbers have the peculiarity of being remarkably resistant to temperature, chemical attacks, and oxidation; they are excellent electrical insulators, non-adhesive, elastic, and resistant to aging. Our range of silicone-coated rollers is an excellent solution for production lines and packaging in the food, pharmaceutical, and cosmetic markets. Mainly mounted on automatic and semi-automatic systems as feeding rollers. Our silicone offers excellent performance where there are high temperatures, the passage of polymeric film, and the need for non-adhesive material.

Polyurethane

Polyurethane coating is mainly employed with ferrous metals. Exceptional service life, ideal for heavy-duty grinding with coarse-grit belts with impressive stock removal. High tear strength, and excellent load-bearing ability.

It can be used in contact with mineral oils and fats. Thanks to its peculiarity, it is used on feeding systems or for coarse grinding operations with hard coatings.

POLYURETHANE & NEOPRENE MOUSSE WHEEL

CHARACTERISTICS:

Very aggressive and noisy wheel despite the sponge flaps helps in reducing the noise during the working cycle. Suitable for high stock removal operations. Standard coating height 15/20mm.

APPLICATION:

Mainly used for ferrous metals operations. Wheels with hard coatings 80-90 Shore A are used for heavy-duty grinding, deburring, and/or where high stock removal is required (e.g. deburring of steel, grinding of turbine blades, and other hard metal workings); lower hardness is suggested for finishing processes.

USE:

- Manual, automatic machines, and robots.

POLYURETHANE WHEEL WITH CROSS GROOVED SLOTS

CHARACTERISTICS:

Polyurethane with special cross grooved coating; standard height 15/20 mm. Extended wear and deformation resistance. The special grooving pattern improves the cutting performance of the belt, extending its life service. Aggressive and noisy wheel.

APPLICATION:

Mainly used for ferrous metals operations. Hard coatings 80-90 Shore A are recommended for heavy grinding operations, deburring, and/or where high stock removal is required (e.g. deburring of steel, grinding of turbine blades, and other hard metal workings); lower hardness is suggested for finishing processes.

USE:

- Manual, automatic machines, and robots.

GUIDE ROLLER

Idler roller coated with 90 Shore A polyurethane, crowned profile. Usually available in standard dimension Ø160x120mm including shaft Ø24x160mm.

However, different dimensions and special characteristics can be manufactured on request.

USE:

- Mounted on grinding machines as belts guiding.

GUIDE ROLLER WITH FLANGES

Guide roller coated with polyurethane 80 Shore A.

USE:

- Widely used on portable machines for grinding and smoothing operations of pipes.